Polyurethane, a synthetic elastomer, is used to create the impact rollers known as urethane rollers. Despite having the word “urethane” in its name, urethane rollers aren’t manufactured of urethane because “urethane” and “polyurethane” are used interchangeably in this context. Therefore, ethyl carbamate, often known as urethane, should not be incorrectly believed to be present in urethane rollers. Read More….

Harwood Rubber Products provides top quality rubber rollers and a variety of custom products. We are capable of producing a great diversity of rolls and coverings for a broad customer base.

Since 1948, REDCO Rubber Engineering & Development has been manufacturing rubber rollers, idler rolls and conveyor rollers. We serve industries such as computers, printers and paper handling.

Our guide rollers are made from the highest quality materials in the industry. We take pride in adhering to our company values, like integrity and honesty. As a family owned and operated company, we like to treat customers like our own family. We will always look for the best prices and the prefect solution. Give us a call today to see how we can help you meet your goals!

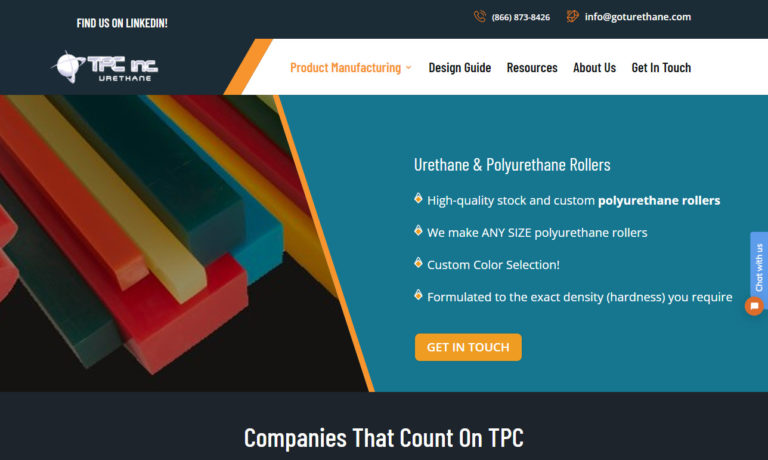

TPC, Inc. is a dedicated and trusted manufacturer of rollers. We manufacture rollers in all shapes, sizes, designs, and colors to meet the needs of our customers and keep their process moving. Our team of experts is dedicated to the production and innovation of our products. As a result, TPC, Inc.’s custom-fit solutions are perfected for customers of all industries.

More Urethane Roller Manufacturers

Types of Urethane Rollers

- Drive Rollers

- Idler Rollers

- Ringer Rollers

- V-Rollers

- Pinch Rollers

- Conveyor Rollers

- Feed Rollers

- Nip Rollers

Benefits of Urethane Rollers

Many of the advantageous characteristics of urethane, such as sturdiness, strength, shock resistance, elasticity, and formability, may be seen in urethane rollers. They are less brittle and harder than many elastomeric materials, including silicone. They are also harder than many other elastomeric materials. Additionally, they don't harm the things with which they come into contact.

Also, it is quite cheap to manufacture urethane rollers. Urethane rollers are among the most often used kind of rubber rollers overall. They are employed in numerous commercial and industrial sectors, including printing, measurement systems, office equipment, packaging and assembly, and data storage. Here are the other advantages of using these rollers since they are made from urethane:

- Chemical/Water Resistance - Urethane beats rubber in applications where rubber would decay over time or metal may rust when exposed to wet environments for an extended time.

- Abrasion/Wear Resistance - Urethane has good abrasion and wear resistance qualities, requiring replacement less frequently. Urethane outperforms natural rubber when rollers are subjected to heavy wear from dynamic loads and high friction. For conveyors, drives, and printing rollers, urethane works well.

- Setting and Rebounding Considerations -Low permanent set and rebound are crucial for printing, driving, and conveyor rollers. Luckily, It is possible to make urethane to support big things without setting.

Tensile Strength and Elongation

Rubber can withstand more pounds per square inch before rupturing and disintegrating than urethane. As a result, systems operating quickly and transporting a lot of weight are especially advantageous for drive and conveyor rollers.

Processes for Urethane Roller Production

Compression and Injection Molding

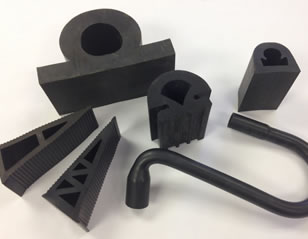

In numerous applications, urethane rollers are employed as part of various commercial and industrial processing machinery, including printers, conveyors, and laminators. They may be thermoformed into almost any shape or size, allowing them to be used in various applications. Manufacturers often use the compression or the injection molding process to achieve this. Manufacturers gather a variety of unprocessed urethane stock and heat it until it melts in both methods.

It is simpler to form as a result since the routes of injection molding and compression molding separate once the raw material has been suitably heated. The now-molten material is then injected into a sealed mold cavity in the case of injection molding. Water is poured over the mold to cool, shape, and cure the roller after the stock has been placed inside the hollow.

When using compression molding, the molten material is poured into an exposed, heated mold once the polyurethane has been heated. Manufacturers close the mold with a plug part or top force once the polyurethane has been placed inside it, applying intense pressure. As a result of this pressure, the molten rubber pushes up against the mold's walls and assumes the shape of the mold.

The new roller finally cures and fully forms while being held by pressure and continuously heated. Once it has cooled and hardened, the roller can be removed from the mold in both injection and compression molding. Compression and injection molding are excellent and efficient ways to make rollers.

Knurling

Manufacturers may prepare the rollers for shipment when they have been made, or they may send them for additional processing. Knurling is a typical form of secondary processing. The surface of rubber or metal objects can be given a rough, patterned texture by knurling. In this context, the goal of knurling, often done on a lathe, is to add grooves or otherwise change the surface area of a roller, resulting in better fits for particular applications.

Urethane rollers are typically altered in either useful or aesthetically pleasing ways. The requirements for weight-carrying capacity, material strengths, system speeds, and industry or governmental standards are the design factors that determine variations the most frequently.

Guidelines and Requirements for Urethane Rollers

Manufacturers typically offer to form rollers up to a variety of codes, such as those outlined by the Federal Drug and Food Administration (FDA), Association for Iron and Steel Technology (AIST), Mil-Spec (military specifications), Restriction of Hazardous Substances Directive (RoHS), International Traffic in Arms Regulations (ITAR), International Standards Organization (ISO), and Registration E (REACH).

What to Consider When Buying Urethane Rollers

Rollers made of urethane are a great investment. They provide elasticity, shock resistance, strength, and formability for various applications. They stand out among other rubber rollers since they are tough but never fragile. Production of urethane rollers is quick, simple, adaptable, and reasonably priced. It should be noted that most manufacturers provide services for refurbishing and remanufacturing old rollers in addition to providing new roller formations.

Choosing the Proper Urethane Rollers Company

To make sure you have the most productive outcome when purchasing urethane rollers from a urethane roller company, it is important to compare at least 5 companies using our urethane roller directory. Each urethane roller company has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the company for more information or request a quote. Review each urethane roller company website using our proprietary website previewer to get an idea of what each company specializes in and then use our simple RFQ form to contact multiple urethane roller companies with the same form.

Urethane Rollers Informational Video

Rubber Extrusions

Rubber Extrusions Rubber Molding

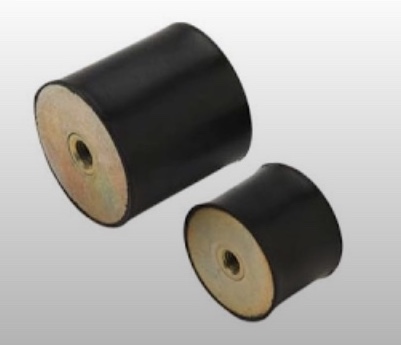

Rubber Molding Rubber to Metal Bonding

Rubber to Metal Bonding Rubber Tubing

Rubber Tubing Vibration Absorbers

Vibration Absorbers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services