The rollers are in place in order to offer additional protection to the conveyor system in places of high impact stress such as loading and transfer points. In addition to impact rollers, there are also a series of other rubber rollers out there for a wide range of applications and industries. Read More…

Harwood Rubber Products provides top quality rubber rollers and a variety of custom products. We are capable of producing a great diversity of rolls and coverings for a broad customer base.

Since 1948, REDCO Rubber Engineering & Development has been manufacturing rubber rollers, idler rolls and conveyor rollers. We serve industries such as computers, printers and paper handling.

Our guide rollers are made from the highest quality materials in the industry. We take pride in adhering to our company values, like integrity and honesty. As a family owned and operated company, we like to treat customers like our own family. We will always look for the best prices and the prefect solution. Give us a call today to see how we can help you meet your goals!

TPC, Inc. is a dedicated and trusted manufacturer of rollers. We manufacture rollers in all shapes, sizes, designs, and colors to meet the needs of our customers and keep their process moving. Our team of experts is dedicated to the production and innovation of our products. As a result, TPC, Inc.’s custom-fit solutions are perfected for customers of all industries.

More Roller Manufacturers

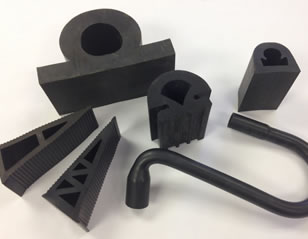

These rollers are utilized in industries such as woodworking, newspaper and print industries, plastic fabrications, medical equipment and material handling (conveyor systems). Whatever your application may be, finding the right roller manufacturer that specializes in the type of roller you are looking for, whether it is an impact roller or a form of urethane roller, is the difference between a good product and a great product.

Impact rollers are in place in order to assist conveyor belt systems in handling their loads in an efficient manner. Guide rollers are in place to protect objects that are on conveyor systems or to assist products such as drawers, doors, fences, and other similar applications in keeping alignment while it is in motion. While urethane rollers that are utilized in the print world are in place to press ink onto paper in a uniform manner. All of these application are very different, which means that there are a lot of specialty manufacturers out there who have years of experience working with each specific style of roller.

A guide roller would not be able to function within an impact roller application as they have a different diameter of shell and typically have a thinner rubber layer, where an impact roller has a smaller core diameter with a large layer of rubber to help absorb the impact. The opposite is also true; an impact roller would not function well within an application meant for a guide roller.If you are unsure of which style of roller is right for your application, or you are simply looking for further information on all types of rollers to gauge what is best for your next job. Fill out a few "request for quote" forms to roller manufacturers to see if they can provide you with the best possible solution based on your requirements and needs.

Rubber Extrusions

Rubber Extrusions Rubber Molding

Rubber Molding Rubber to Metal Bonding

Rubber to Metal Bonding Rubber Tubing

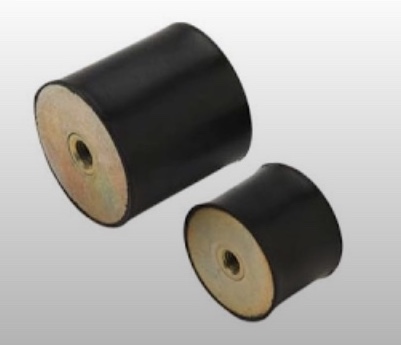

Rubber Tubing Vibration Absorbers

Vibration Absorbers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services