Rubber rolls are simply large rolls of processed synthetic or natural rubber. In the production of rubber, rubber is manufactured in a liquid state. After the rubber forms, it is removed from the liquid and rolled between rollers to smooth the rubber and remove excess moisture. These rubber sheets are then rolled into large rolls and sent to other factories for various uses. You can find rubber rolls used for many of the following manufacturing processes:

Flooring covers: One of the uses for a rubber roll is as a flooring cover. Rubber is an ideal material for a flooring cover because it is resistant to moisture and provides a high level of traction. Rubber mats and floors are used to provide cushioning for individuals who stand for long periods of time, including many industrial workers. Sometimes the rubber is used just as it comes off the production line and other times the rubber is dotted with holes or given additional lines for extra traction or comfort.

Product protectors: Rubber sheets are also used to protect objects from various liquids and exposures, such as from salt water, ozone, chemicals, UV light, and oxidation. Rubber is highly resistant to these materials, which is why you often see rubber used to protect more delicate materials like wood. Rubber sheets provide an easy way to add protection around an object quickly, such as a floor topper for a boat or a cover over an iron object.

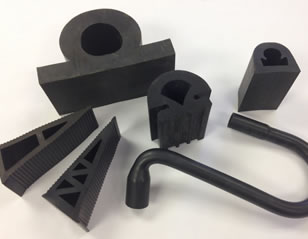

Shaped products: Rolls of rubber are also shipped to other factories for additional processing. Often, rubber is cut with dies and punches to create smaller rubber objects. Some of the many objects made this way include shoe soles, rubber erasers, and more. Some rubber sheets are melted down and poured into molds to create other rubber products, like bicycle handle grips, rubber balls, and other items.

Rubber Extrusions

Rubber Extrusions Rubber Molding

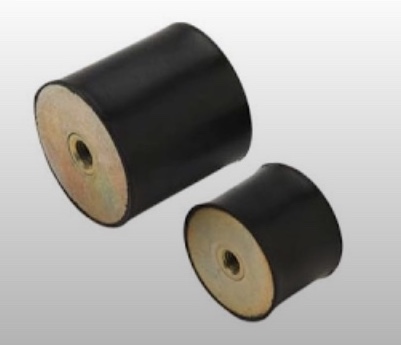

Rubber Molding Rubber to Metal Bonding

Rubber to Metal Bonding Rubber Tubing

Rubber Tubing Vibration Absorbers

Vibration Absorbers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

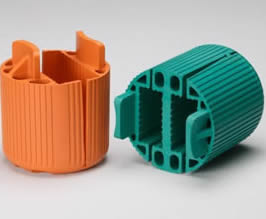

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services