Ink rollers, also known as rubber rollers, are essential tools for many industries, including printing, textiles, industrial manufacturing, food processing, and medical and pharmaceutical industries. Ink rollers play a crucial role in the application of ink to various materials, making them an integral part of the manufacturing process. In this article, we will discuss the creation and variations of ink rollers, as well as the environmental and health and safety considerations that come with their use. We end this article by discussing the benefits and various applications of ink rollers Read More…

Harwood Rubber Products provides top quality rubber rollers and a variety of custom products. We are capable of producing a great diversity of rolls and coverings for a broad customer base.

Since 1948, REDCO Rubber Engineering & Development has been manufacturing rubber rollers, idler rolls and conveyor rollers. We serve industries such as computers, printers and paper handling.

Our guide rollers are made from the highest quality materials in the industry. We take pride in adhering to our company values, like integrity and honesty. As a family owned and operated company, we like to treat customers like our own family. We will always look for the best prices and the prefect solution. Give us a call today to see how we can help you meet your goals!

TPC, Inc. is a dedicated and trusted manufacturer of rollers. We manufacture rollers in all shapes, sizes, designs, and colors to meet the needs of our customers and keep their process moving. Our team of experts is dedicated to the production and innovation of our products. As a result, TPC, Inc.’s custom-fit solutions are perfected for customers of all industries.

More Ink Roller Manufacturers

The Creation of Ink Rollers

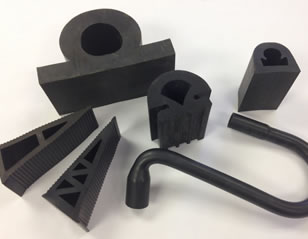

Ink rollers can be created using various methods, including injection molding, compression molding, transfer molding, and extrusion. The chosen method depends on the type of material and the desired characteristics of the ink roller. Injection molding is a popular method used to create ink rollers from synthetic and natural rubber. This method involves melting the rubber and injecting it into a mold, which is then cooled and removed. Compression molding involves compressing the rubber into a heated mold, while transfer molding involves heating the rubber and transferring it into the mold using a plunger. Extrusion, on the other hand, involves forcing the rubber through a die to create a continuous sheet that is then cut into the desired shape.

Variations in Ink Rollers

Ink rollers can vary in design and material. Design variations include smooth or textured surfaces, straight or tapered edges, and solid or hollow construction. Material variations include natural rubber, synthetic rubber, silicone, and polyurethane. Each variation has its own advantages and disadvantages, depending on the intended application. For example, silicone rollers are ideal for use in food processing because they are odorless and do not react with food, while natural rubber rollers are ideal for printing because they have excellent ink transfer properties.

Considerations Regarding Ink Rollers

Ink rollers, like many other products, provide many considerations regarding their use. For example, ink roller production can have an environmental impact due to the use of chemicals and energy. Meanwhile, the disposal of used ink rollers can lead to environmental pollution if not properly handled. Additionally, workers in ink roller production may be exposed to harmful chemicals and fumes and there is a risk of ink transfer to the skin or eyes when using them, which can cause irritation or other health problems.

The Benefits of Ink Rollers

Ink rollers provide consistent and precise application of ink to various materials. Meanwhile, they can improve efficiency and productivity in manufacturing processes. Additionally, ink rollers are versatile and can be used in many industries, including printing, textiles, and food processing. They can also be customized to fit specific application needs, such as different materials and ink types.

Applications of Ink Rollers

As previously mentioned throughout this article, ink rollers find usefulness in a variety of applications. We now explain these applications in greater detail below.

Printing

Ink rollers are commonly used in printing processes to apply ink to various surfaces, such as paper, cardboard, and metal. They can be used in printing presses, including offset, flexographic, and letterpress, to transfer ink from the printing plate to the substrate. Ink rollers play a key role in ensuring accurate and consistent ink application, resulting in high-quality printed materials.

Textiles

Ink rollers are also used in textile printing to apply ink to fabrics, such as cotton, silk, and polyester. They can be used in screen printing, roller printing, and digital printing processes. Ink rollers help to ensure even and precise ink application, resulting in vibrant and durable printed textiles.

Industrial Manufacturing

Ink rollers are used in industrial manufacturing processes to mark and label products, such as packaging materials, pipes, and metal sheets. They can be used in inkjet printing, pad printing, and other marking and coding technologies. Ink rollers help to ensure clear and readable marks, which are essential for product identification, tracking, and traceability.

Food Processing

Ink rollers are also used in food processing and packaging to label products, such as meat, dairy, and snack items. They must meet strict safety and regulatory requirements, such as being food-grade and non-toxic. Ink rollers play a crucial role in ensuring accurate and legible labeling, which is important for food safety and compliance.

Medical and Pharmaceutical Applications

Ink rollers are used in medical and pharmaceutical applications to label products, such as syringes, medical devices, and prescription drugs. They must meet strict regulatory requirements, such as being sterile and resistant to sterilization processes. Ink rollers help to ensure accurate and consistent labeling, which is important for patient safety and regulatory compliance.

Choosing the Right Ink Roller Supplier

To ensure you have the most productive outcome when purchasing ink rollers from an ink roller supplier, it is important to compare several companies using our directory of ink roller suppliers. Each ink roller supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or to request a quote. Review each ink roller business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple ink roller companies with the same form.

Rubber Extrusions

Rubber Extrusions Rubber Molding

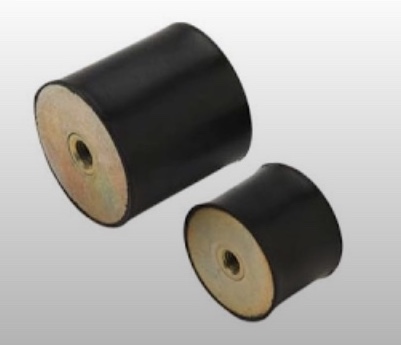

Rubber Molding Rubber to Metal Bonding

Rubber to Metal Bonding Rubber Tubing

Rubber Tubing Vibration Absorbers

Vibration Absorbers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services