Conveyor Rollers & Conveyor Rolls

Conveyor rollers are an essential component of the manufacturing process that work as part of a unit to transport products or even loose bulk materials like coal, sand, or iron ore. Conveyor rollers are logically thought of as material-handling components with a cylindrical shape. Conveyor rollers are supported by a carrying structure that is propelled by a chain, a belt, or gravity. Additionally, there are drive rollers which have an integrated motor to motorize roller conveyors, eliminating the need for an additional drive unit; in this instance, materials are transported by a conveyor belt, which loops around pulleys and rollers. Read More…

Harwood Rubber Products provides top quality rubber rollers and a variety of custom products. We are capable of producing a great diversity of rolls and coverings for a broad customer base.

Since 1948, REDCO Rubber Engineering & Development has been manufacturing rubber rollers, idler rolls and conveyor rollers. We serve industries such as computers, printers and paper handling.

Our guide rollers are made from the highest quality materials in the industry. We take pride in adhering to our company values, like integrity and honesty. As a family owned and operated company, we like to treat customers like our own family. We will always look for the best prices and the prefect solution. Give us a call today to see how we can help you meet your goals!

TPC, Inc. is a dedicated and trusted manufacturer of rollers. We manufacture rollers in all shapes, sizes, designs, and colors to meet the needs of our customers and keep their process moving. Our team of experts is dedicated to the production and innovation of our products. As a result, TPC, Inc.’s custom-fit solutions are perfected for customers of all industries.

More Conveyor Roller Manufacturers

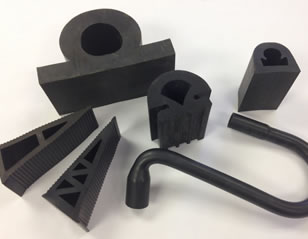

Conveyor rollers may be created from various materials like plastic, aluminum, or steel. In order to improve the grip of conveyor rollers that are commonly built from these materials and to provide additional protection from goods slipping during the manufacturing process, many rollers use a rubber coating specifically designed for such rollers. Other conveyor rollers are made directly with rubber rollers.

Conveyor rollers with rubber coatings enable more friction between the roller and the driving belt. This is extremely helpful where there would othewise be belt slippage. Additionally, a non-marking rubber coating can be utilized to prevent marking where the product is likely to be easily marked by accident.

How Conveyor Rollers Work

The conveyor roller helps to hold the conveyor belt in place. The conveyor belt has an outward segment and a return section because it makes an unending loop around pulleys at the location where the materials are fed onto the belt, or feed point. The conveyor belt's job is to move the goods to a discharge point, where these items come off the belt once more.

The upper, or carry, section refers to the portion of the conveyor belt that faces outward and moves with the material from the feed point to the discharge point. From the discharge point to the feed point, the bottom part, or return section, goes backward devoid of any material. At various points, the conveyor rollers support and direct the conveyor belt.

Types of Conveyor Rollers

Chain-Driven Conveyor Rollers

Chain-driven roller systems consist of a series of rollers connected to a motor. Such systems may operate in one of two ways. With chain-driven loops, power is transferred from roller to roller. They are used when heavy-duty carrying is required but regular belt-driven conveyors cannot be used because of such hard conditions.

The other method is through the use of a tangential chain roller conveyor, which is used where long, motorized conveying paths are required. This conveyor is only rated for medium to heavy-duty use since it is not as powerful as its roll-to-roll counterpart, even though the chain is continuously engaged at all times by a continuous hold-down region.

Belt-Driven Conveyor Rollers

Belt-driven rollers are another popular operational roller method. Under this system, a belt is used to operate a series of rollers. There are a variety of different belt-driven rollers systems including live roller systems, curved roller systems, and many more. Each roller on the belt-driven live roller conveyor is driven by a motorized belt, which enables this conveyor to regulate the flow of the items being delivered. They are preferred over ordinary belt conveyors when items need to be temporarily stopped at control points, when products need to be turned, or where side unloading or slide loading is needed.

The belt for curved roller conveyors can be straight or V-shaped. These systems are designed to carry items around curves or corners. Some belt-driven roller conveyors include rollers that are taller than the frame, allowing them to accommodate loads greater than the width of the frame. These conveyors are typically used to move medium to large products that need to be kept dry and clean and occasionally paused or operated in the other direction.

Benefits of Conveyor Rollers

- Conveyor rollers provide a great deal of versatility and provide an infinite number of solutions for material handling problems because they are modular in design.

- They are simple to install, dependable, and require little maintenance.

- Conveyor rollers provide an affordable method of moving things during production processes.

- Conveyor rollers reduce problems with manual handling along manufacturing and distribution processes.

- Conveyor rollers can also be added to powered systems as a system demands.

- Curved roller sections, spurs, and a variety of other options can be used to connect straight runs of roller conveyors.

- Conveyor rollers may feature rubber rollers or be easily adapted with rubber coatings which have a distinct benefit because of their soft coating, which offers a firm grip for increased traction and additional protection for cargo as it moves down a conveyor system.

- Rollers with a rubber coating are more resilient than metal rollers of the same size and help absorb stress for items moving along production lines.

- The natural give and flexibility of rubber-coated rollers provide uniform weight distribution across the roller rather than concentrated pressure at the point of contact.

Choosing the Proper Conveyor Roller Manufacturer

To make sure you have the most positive outcome when purchasing conveyor rollers from a conveyor roller manufacturer, it is important to compare at least 5 manufacturers using our conveyor roller directory. Each conveyor roller manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each conveyor roller business with our proprietary website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple conveyor roller manufacturers with the same form.

Rubber Extrusions

Rubber Extrusions Rubber Molding

Rubber Molding Rubber to Metal Bonding

Rubber to Metal Bonding Rubber Tubing

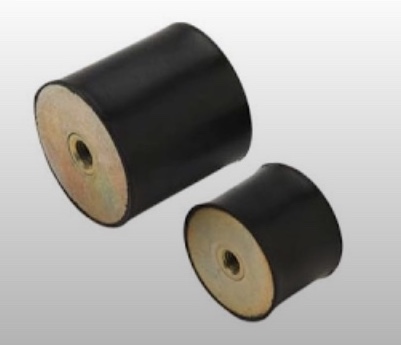

Rubber Tubing Vibration Absorbers

Vibration Absorbers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services